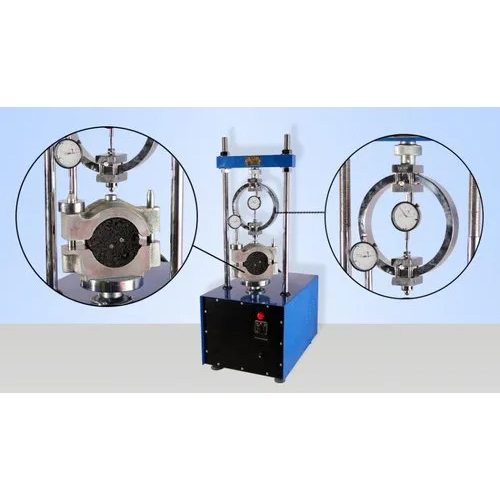

PVC Pipe Testing Machine

Price 105000 INR/ Unit

PVC Pipe Testing Machine Specification

- Voltage

- 220 Volt (v)

- Display Type

- Digital / LCD Display

- Interface Type

- USB / RS232

- Hardness

- As per IS standard

- Automation Grade

- Semi-Automatic / Automatic

- Humidity

- Up to 95% RH, non-condensing

- Material

- Metal

- Mounting Type

- Floor mounted

- Application

- Tensile and pressure testing of PVC pipes

- Power Supply

- Electric

- Usage

- Industrial

- Port Size

- 1/2 inch to 4 inch (customizable)

- Equipment Type

- PVC Pipe Testing Machine

- Product Type

- PVC Pipe Testing Machine

- Number of Specimens

- 1 to 3 per cycle

- Resolution

- 0.01 mm

- Test Range

- 0-1000 kg

- Max Height

- 1400 mm

- Features

- Automatic data recording, Safety lock, Overload protection

- Test Speed

- 10-50 mm/min (variable)

- Test Stroke

- 0-500 mm

- Control Mode

- Digital Control / PLC Control

- Protection Class

- IP54

- Motor Type

- Servo Motor / Stepper Motor

- Color

- Blue / Grey (custom options available)

- Calibration

- Factory calibrated, certificate provided

- Cycle Time

- 30-300 s adjustable

- Clamp Type

- Self-centering clamps

- Software

- PC-based test management software provided

PVC Pipe Testing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 20 Days

- Main Domestic Market

- All India

About PVC Pipe Testing Machine

| Material | Stainless Steel |

| Brand | Shambhu Nath & Sons |

| Weight | Upto 170 kg |

| Voltage | 220 V |

| Pipe Diameter Range | 2 - 1600 mm |

| Pressure Resolution | 0.001Mpar ( 0.01bar or 1PSI) |

| Timing Mode | Counter-up,counter-down |

| Timing Range | 0 - 10000h |

| Control Mode | Desktop PC |

FAQs of PVC Pipe Testing Machine:

Q: How does the PVC Pipe Testing Machine ensure precise measurement during tests?

A: The machine provides high accuracy (1%) and a fine resolution of 0.01 mm through its digital control and factory calibration. Automatic data recording and advanced sensors ensure reliable and repeatable measurements for tensile and pressure testing.Q: What type of motors power this equipment and how do they improve testing?

A: The PVC Pipe Testing Machine utilizes servo motors or stepper motors, which offer precise control of test speed and stroke. This contributes to consistent and adjustable testing cycles, enhancing the quality of test results.Q: When should I calibrate the machine, and is a calibration certificate included?

A: Calibration is factory-set for each unit, and a calibration certificate is provided upon delivery. This ensures immediate testing accuracy; however, periodic calibration recommendations depend on usage frequency and industry standards.Q: Where can the PVC Pipe Testing Machine be installed and used?

A: Designed for industrial environments, the machine is floor-mounted and suited for test labs, manufacturing units, and QA departments dealing with PVC pipe testing. It operates efficiently within ambient temperatures up to 50C and humidity up to 95% RH.Q: What is the process for tensile and pressure testing on this machine?

A: Users position up to three PVC pipe specimens in self-centering clamps, set the test parameters via PC software, and initiate the cycle. The machine measures tensile force and pressure, records data automatically, and displays results through the digital or LCD display.Q: How does the machine benefit my businesss quality assurance procedures?

A: With automatic data recording, high accuracy, adjustable cycles, overload protection, and comprehensive software integration, the machine streamlines testing, ensures product quality, and supports compliance with Indian standards. Customizable options further adapt the system to specific needs.Q: What kind of pipes and specimen sizes are supported by the equipment?

A: The machine accommodates PVC pipes with port sizes from 1/2 inch to 4 inch and specimen diameters from DN20 to DN100 mm, covering a wide range of industrial testing requirements. Custom port sizes are also available on request.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Testing Machine Category

Tensile Testing Machine

Price 42000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Overload protection, data logging, automatic shutoff

Resolution : 0.01 kN

Test Range : 0 100 kN

Number of Specimens : 1 at a time

Pendulum Impact Testing Machines

Price 35000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : High Sensitivity, Robust Construction

Resolution : 0.1 J

Test Range : 0300 Joules

Number of Specimens : 1

Marshall Stability Testing Machine

Price 65000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Rugged construction, stable base, precise loading rate, easy operation

Resolution : 0.01 kN

Test Range : 050 kN

Number of Specimens : Single specimen per cycle

Box Compression Testing Machine

Price 85000 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Automatic peak hold, User friendly interface, Data memory

Resolution : 0.01 kN

Test Range : 0 50 kN

Number of Specimens : Single specimen per test

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free